RENNER

REal-time acquisitioN and NEural Representation of structural properties

A project funded by Villum Synergy 2022 grant

Vedrana Andersen Dahl, DTU Compute, and Jens Wenzel Andreasean, DTU Energy

Summary of the application

When using X-ray imaging to quantify structural properties of materials, data acquisition is typically carried out under the best possible experimental conditions to attain the highest image quality. This is because subsequent analysis steps, reconstruction, and segmentation, rely on high-quality data. We propose to invert the experimental design and optimize for maximum speed, facilitating real-time measurements.

Our real-time structural characterization will provide immediate feedback for controlling the properties of materials, as they are being manufactured. We have chosen to focus on highly anisotropic composite materials, specifically pultruded unidirectional composites of high-performance fibres, quantifying fibre orientation and alignment. However, the methodology developed in this project may be adapted to other materials and structural properties.

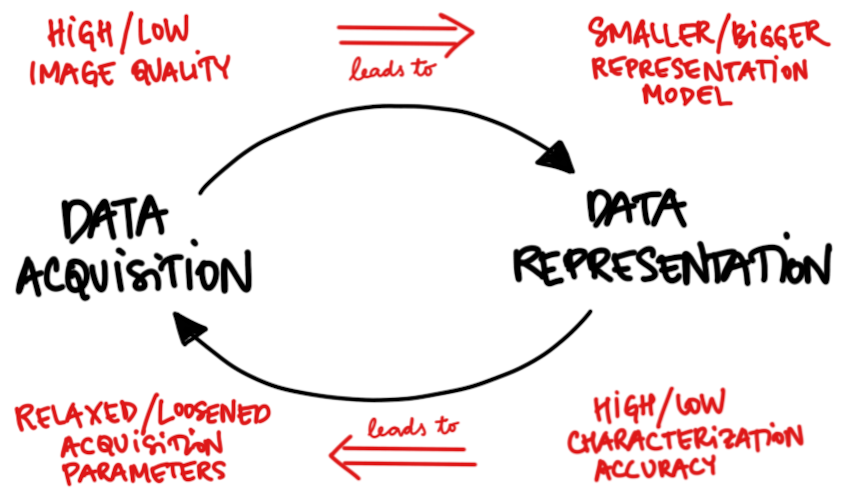

By applying our complementary competences for developing experimental data acquisition and data representation in parallel, we will exploit a feedback loop between two lines of development. The quality of characterization allows us to determine how much we can relax the experimental parameters while still accurately determining the desired property.

Research proposal

High-performance composite materials are used in sustainable energy (wind turbine blades), transportation (automotive and structural aerospace material), biomechanical prosthetics, and many other areas. The manufacture of unidirectional composites is increasingly taking place by a pultrusion process where fibre yarns are continuously impregnated with a polymer resin. During pultrusion, the material is subject to a carefully adjusted set of processing parameters (tension, temperature, and processing speed) determining the mechanical properties of the end material. Although the processing parameters are relatively easy to control and measure in real-time, the developing structure is much more difficult to monitor and is usually only probed off-line. Here, X-rays are typically used as they allow characterization of nano and microstructure without destructive sample preparation or high vacuum at the sampling position.

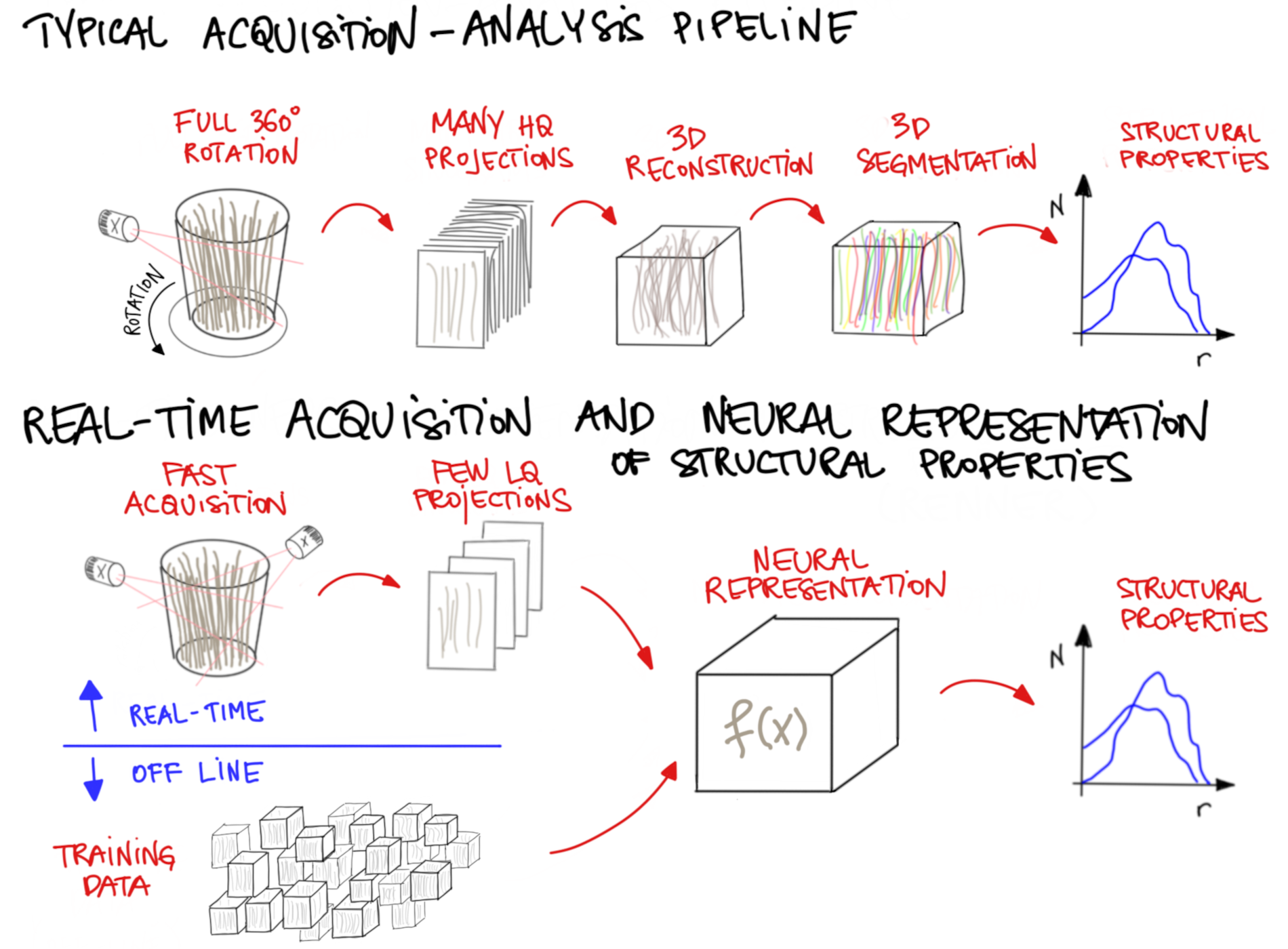

Our aim is to develop a methodology that allows for in-line characterization of material properties, sketched in Figure 1. For this, we will create a novel acquisition approach and demonstration of instrumentation for the fastest possible few-projection X-ray imaging, motivated by recent work on plenoptic imaging. The real-time acquisition will be coupled with novel neural image representation, replacing reconstruction and segmentation. This neural representation will be pre- trained on high-quality data, allowing it to predict material properties from only a few real-time projections. This combination of novel data acquisition and novel data representation will allow for the immediate identification of structural properties of the imaged material.

Figure 1 RENNER will use few-projections imaging and neural representation of acquired data for real-time characterization of materials.

Figure 2 Feedback loop between acquisition and representation. The quality of acquired images influences the size of the representation. On the other hand, the accuracy of characterization influences acquisition parameters.

We focus our investigation on composite materials, which are available in large volumes and have been thoroughly characterized in their final state. The availability of structural quantifications for these materials enables us to build detailed structural models of the materials such that we can establish how much we can relax the experimental parameters while still accurately determining a certain property, e.g., fibre orientation distribution, in real-time. However, the methodology developed in the project, both the imaging and the analysis, will be applicable to other materials and properties.

The full impact of our proposed approach is only achievable by developing data acquisition and data representation in parallel, exploiting the feedback loop in Figure 2. Developing only data acquisition, we would not know whether the acquisition quality is sufficient, and we could not optimize for acquisition speed by relaxing experimental parameters. Developing only data representation, possibly on synthetically generated data, we would not be able to appropriately scale the neural model, for optimal memory and computation requirement while still accurately representing real data.

Using neural representations to learn structural properties from sparse projection data will be groundbreakingly novel. Such representations have only recently emerged as fast, compact, and flexible options for 3D reconstruction from multi-view cameras and real-time rendering. Only a few attempts have been made in using neural representations for tomographic reconstruction.

The characterization of composite materials has traditionally been done off-line which can be adequate for the typical batch type processing. For a continuous process like pultrusion, however, an in-line and real-time characterization technique is needed, to leverage the possibility of optimizing structural properties on the fly. This can be seen as the holy grail of Industry 4.0 where the use of massive volumes of real-time data allows instantaneous feed-back to the process control parameters, thus minimizing material waste, and maximizing the output of the highest quality material.

To our knowledge, no other research efforts are taking a similar approach to tackle real-time characterization of micro-structure as it is developed in real industrial processes. Classical approaches are based on faster hardware, more intense X-ray sources, and faster reconstruction algorithms, whereas we focus on acquiring just the pertinent, necessary data. We consider our unique approach and close-knit collaboration to constitute our distinct competitive edge with respect to other strategies.